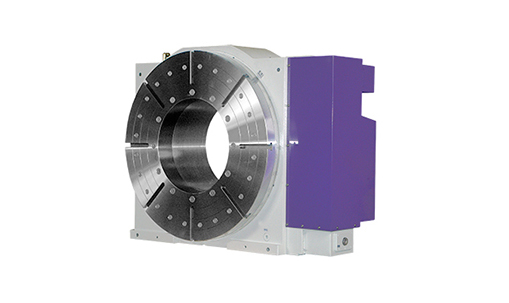

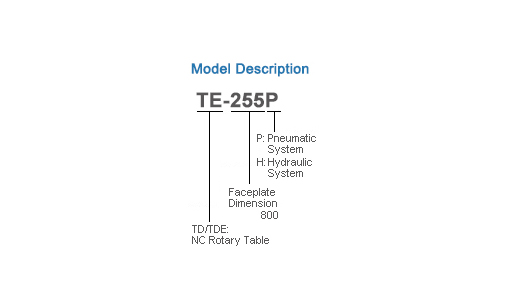

TE-800H

NC Rotary Table (0.001°)

TE-800H

Large Pore Size Series

- Adopted patented disk hydraulic clamping system . It can assure heavy and steady cutting without any deviation from the centre (TE-800).

- The feature of wear resistant alloy Dual-Lead Worm Gear is high mechanical e-ciency of power transmission, high indexing accuracy, and easy adjusted on the backlash.

- Driven by the servo Motor. E-ciently in position, high accuracy, Low noise and suitable for any angles working piece.

- It can be added with air booster or hydraulic unit.

- It can be connected with CNC machine as a 4th Axis or matched with Single Axis Controller as an additional Axis.

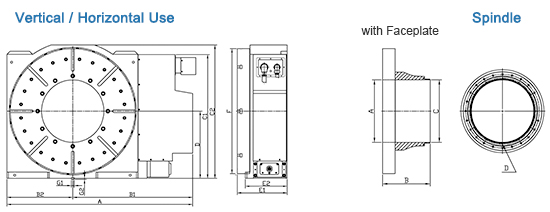

| Use Method | Vertical / Horizontal Use | |

|---|---|---|

| Clamp Method | Hydraulic 35kg/cm2 | |

| Faceplate Dimension | Ø800mm | |

| Spindle Through Hole Diameter | Ø400mm | |

| Faceplate Centre Hole Diameter | Ø400H7mm | |

| Centre Height | 430mm | |

| Faceplate T-Slot Width | 18H7mm | |

| Position Key | 18H7mm | |

| Servo Motor | • FANUC | α12i |

| •MELDAS | HF204S | |

| Total Speed Reduction Ratio | 1/180 | |

| Min. Increment Unit | 0.001° | |

| Indexing Accuracy | 20 (Arc. Sec.) | |

| Repeatability | 4 (Arc. Sec.) | |

| Clamp Force | 700kgf-m | |

| Max. Torque Capacity of Worm Gear | 800kgf-m | |

| Max. Workpiece of Capacity | • Workpiece Vertical (With Tailstock ) |

600(1500)kg |

| • Horizontal | 1500kg | |

| Net Weight (Without motor) | 950kg | |

Unit: mm

| The outline of dimension | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TE-800H | Servomotor cover type |

A | B1 | B2 | C1 | C2 | D | E1 | E2 | F | G1 | G2 |

| Vertical / Horizontal Use | 1061 | 639 | 422 | 792.6 | 853 | 430 | 426.8 | 268 | Ø800 | M18 | 7 | |

Unit: mm

| Spindle Dimension | ||||

|---|---|---|---|---|

| Faceplate | A | B | C | D |

| Yes | Ø400 X 92L | 317 | Ø400 X 92L | 12-M5X15L,Ø425 |