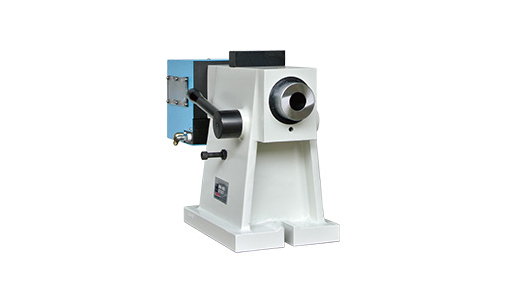

Tailstock

Model

Clamp Type

Control Method

Types of Lathe Tailstock

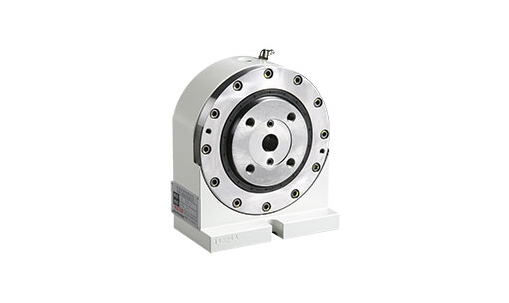

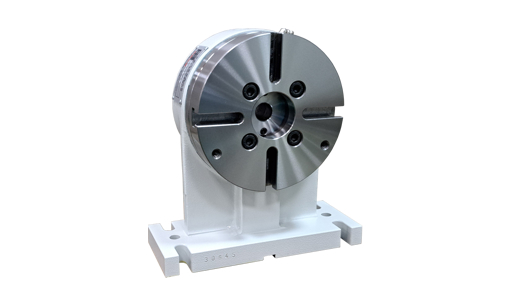

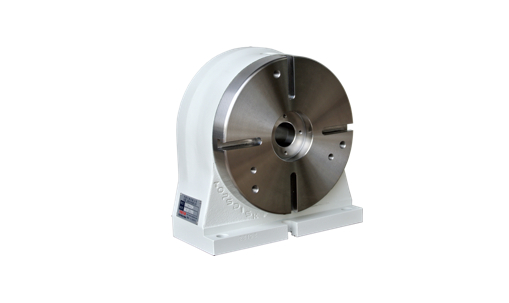

Vertical Rotary TableFaceplate Tailstock

Faceplate tailstock usually consists of a large panel and a support slide, there are many holes on the panel for clamping workpieces or fixtures which can provide additional support and stability for machining larger or complex workpieces mainly used for turning larger workpieces.

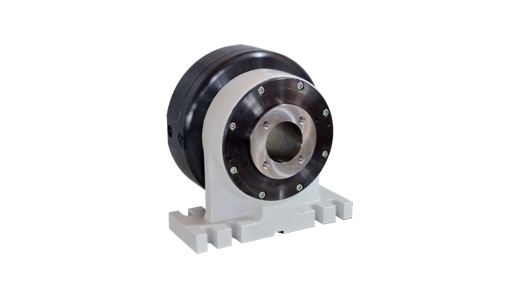

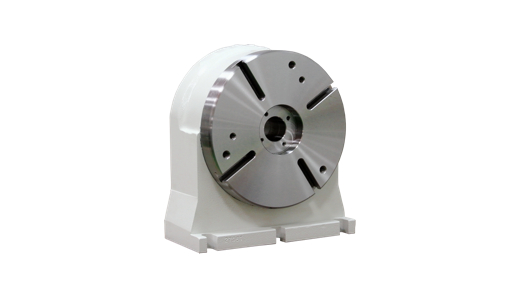

Center Type Tailstock

The workpiece is mainly supported through the central hole and is good support and stability help reduce workpiece deformation usually used to process rotationally symmetrical workpieces, such as cylinders and shafts.

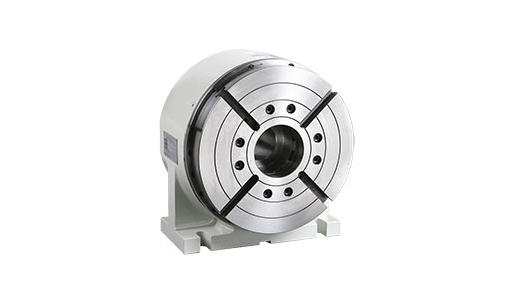

Manual Tailstock

The manual tailstock usually consists of a movable slide base and a ratchet in the tailstock, and the position is adjusted by rotating the handle or propeller which is simple to operate, low in cost can be used to general turning processing workpieces of various sizes and shapes.

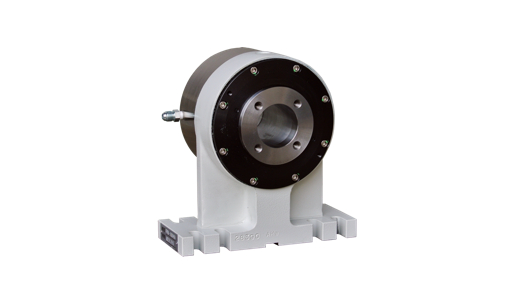

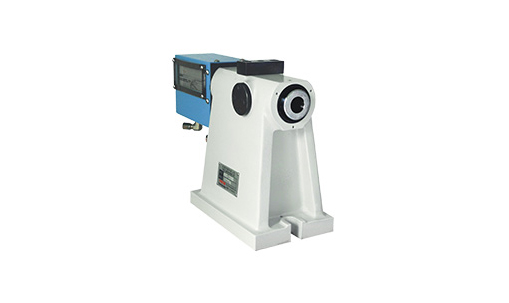

Pneumatic Tailstock

The pneumatic tailstock controls the clamping force through compressed air and usually has automatic and manual operating modes. In automatic mode, the clamping force can be automatically adjusted according to preset parameters, while in manual mode, operator control is required.

The pneumatic tailstock has the characteristics of quick clamping and releases suitable for working environments requiring high-speed and efficient processing, such as automated processing in mass production.

Hydraulic Tailstock

The hydraulic tailstock uses the hydraulic system to generate clamping force, and different clamping effects can be achieved by adjusting the pressure to provide high-precision clamping force control, making processing more stable and precise commonly used in situations where high-precision processing is required, such as processing of precision parts or high-precision turning.