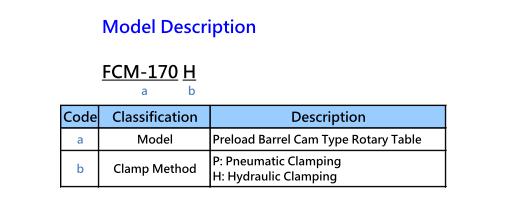

FCM-170P / FCM-170H

- Standard pressure switch reduces maintenance opportunities.

- A Solenoid valve and pressure switch are installed outside to avoid moisture inside the rotary table to damage electrical components.

- Directly equipped with the absolute motor, no need to Zero return when starting up.

FCM-170P / FCM-170H vertical roller cam rotary table adopts a preloaded barrel cam mechanism that provides zero-clearance drive and has incomparable advantages over other mechanism rotary tables.

The transmission element is made of steel, which is more rigid than copper and a stronger eccentric load provides excellent working accuracy and efficiency. Double action pneumatic or hydraulic brake mechanism to ensure full unclamps, rolling friction transmission effectively avoids internal parts loss and extends operation life.

| Specification | FCM-170P | FCM-170H | |

|---|---|---|---|

| Use Method | Vertical | ||

| Clamp Method | Pneumatic 5kg/cm2 | Hydraulic 35kg/cm2 | |

| Faceplate Dimension | Ø170mm | ||

| Spindle through hole | Ø45mm | ||

| Faceplate centre hole | Ø50mmH7 | ||

| Centre Height | 135mm | ||

| Faceplate T-slot width | 12mmH7 | ||

| Position key | 14mmh7 | ||

| Absolute servo motor |

FANUC | α4i/β8i Straight shaft | |

| MELDAS | HF-104S | ||

| Yaskawa | SGM7G-09 | ||

| Siemens | 1FK-7060-****-1RG1 | ||

| Reduction ratio | 1/36 | ||

| Min. Increment Unit | 0.001° | ||

| Indexing Accuracy | ±20(Arc.Sec.) | ||

| Repeat Accuracy | 10(Arc.Sec.) | ||

| Clamp Force | 26kgf-m | 100kgf-m | |

| * Maximum RPM (3 sec) | 83rpm@ motor 3000rpm | ||

|

* Max. Workpiece of Capacity (within faceplate diameter) |

Vertical only | 50kg | |

| Vertical (with tailstock) |

100kg | ||

| * Cam torque | Continuous | 146Nm@10rpm | |

| Maximum | 307Nm | ||

| Net weight | without motor but with faceplate | 65kg | |

Note:* above table is the data within the diameter of faceplate, if it exceeds the faceplate, the same maximum inertia value must be calculated as the limit.

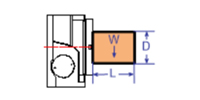

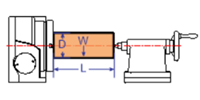

| Balanced Load | No Tailstock |  |

W:50kg D:Ø170mm L: 250mm |

|---|---|---|---|

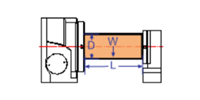

| using Faceplate Tailstock |  |

W:100kg D:Ø170mm L: 600mm |

|

| using manual Tailstock |  |

W:80kg D:Ø170mm L: 700mm |

|

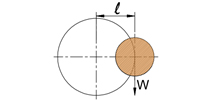

| Eccentric Load | using Tailstock |  |

Eccentric Load= l x W W:1.5kg-m |

Note:The maximum load value is only one of the three conditions (weight W, rotation diameter D, length L) can be satisfied.

- The hydraulic unit at least one circuit (DC24V/2B2 solenoid valve).

- The machine must has the fourth axis function, absolute motor and amplifier.

- Conduit Cable (Length depends on machine condition)

- Two oil pipes. (Length depends on machine condition)

- Pressure switch, 5m cable.

- Three bolt sets and T-blocks. (match with position key 14mm; T-slot pitch 100 and 125mm)

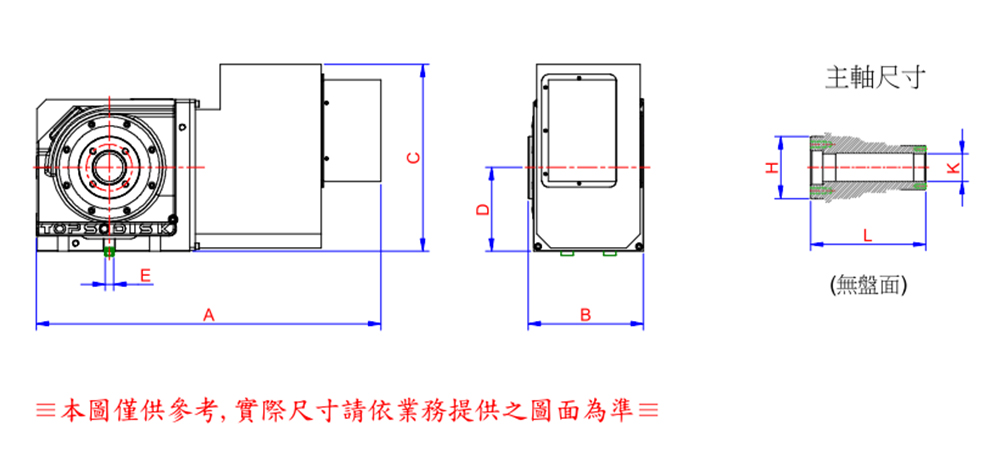

| FCM-170 | total width(A) | Total thickness(B) | Total height(C) | Centre height(D) | Spindle through hole(K) | Spindle OD(H) | Spindle length(L) | Screw Pitch, Slot Width(E) |

|---|---|---|---|---|---|---|---|---|

| No faceplate | 564 | 189 | 302 | 135 | Ø45 | Ø100 | 188 | middle , 14 |