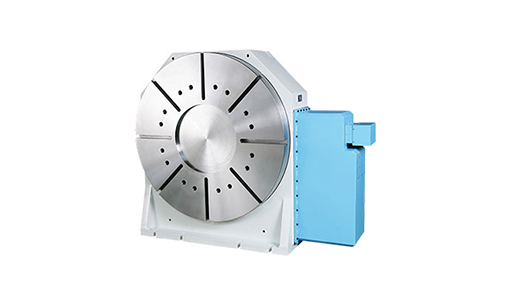

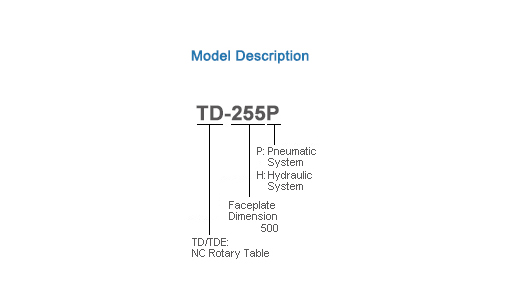

TD-1000H

NC Rotary Table (0.001°)

TD-1000H

Standard Series

- Adopted patented disk hydraulic clamping system . It can assure heavy and steady cutting without any deviation from the centre.

- The feature of wear resistant alloy Dual-Lead Worm Gear is high mechanical e-ciency of power transmission, high indexing accuracy, and easy adjusted on the backlash.

- Driven by the servo Motor. E-ciently in position, high accuracy, Low noise and suitable for any angles working piece.

- It can be added with air booster or hydraulic unit.

- It can be connected with CNC machine as a 4th Axis or matched with Single Axis Controller as an additional Axis.

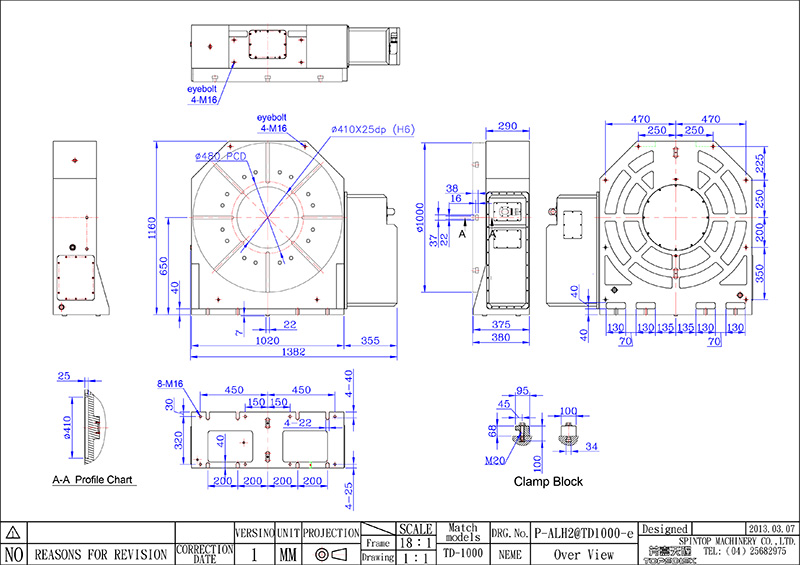

| Use Method | Vertical / Horizontal Use | |

|---|---|---|

| Clamp Method | Hydraulic 35kg/cm2 | |

| Faceplate Dimension | Ø 1000 mm | |

| Spindle Through Hole Diameter | Ø 410 mm | |

| Faceplate Centre Hole Diameter | Ø 410H6 mm | |

| Centre Height | 650 mm | |

| Faceplate T-Slot Width | 22H7 mm | |

| Position Key | 22h7 mm | |

| Servo Motor | • FANUC | α22 |

| •MELDAS | HC-202SE51 | |

| •Heidenhain | QSY-155D-ERN1387 | |

| Total Speed Reduction Ratio | 1/360 | |

| Min. Increment Unit | 0.001° | |

| Indexing Accuracy | 20 (Arc. Sec.) | |

| Repeatability | 4 (Arc. Sec.) | |

| Clamp Force | 1200kgf-m | |

| Max. Torque Capacity of Worm Gear | 1000 kgf-m | |

| Max. Workpiece of Capacity | • Workpiece Vertical | 1000kg |

| • Horizontal | 3000kg | |

| Net Weight (Without motor) | 2332kg | |