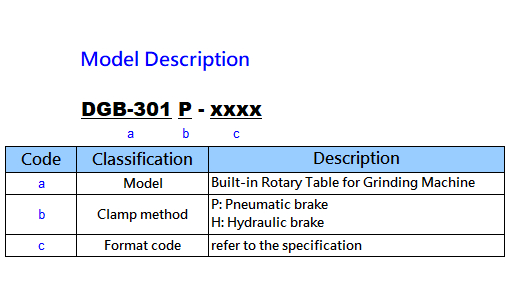

DGB-301 / DGB-301P

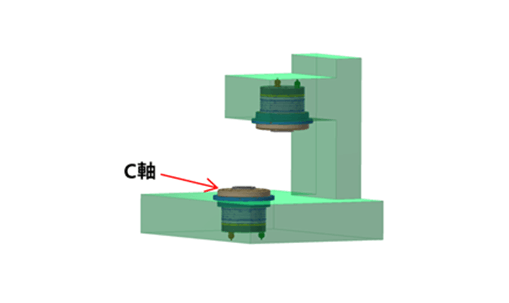

Rotary Table for CNC Grinding Machine(C Axis)

DGB-301 / DGB-301P

Built-in (Spindle up)

- Direct motor drive, no backlash.

- Suitable for simultaneous machining, applied to rotary table for tool axis (C axis).

- Reserved cooling grooves, customers can add cooling circuit to the body.

- Min.division degree: 0.001 degree.

- Install various encoders according to accuracy requirements.

| Popular Model | ◎ | |

|---|---|---|

| Specification | DGB-301-RBGD | DGB-301P-RBGD |

| Use Method | Built-in (Spindle up) | |

| Cooling | cooling groove | |

| Clamp method | No Brake | Pneumatic 5kg/cm2 |

| Spindle Through Hole diameter | Ø40mm | |

| Spindle Endface Diameter | Ø70x15L mm | |

| Solenoid valve and detection | NO | External connection required |

| Maximum Speed (1 sec.) | 150rpm | 150rpm |

| Continuous Speed | 75rpm | 75rpm |

| Maximum Current (1 sec.) | 13.5A / Cooling 22.5A | 13.5A / Cooling 22.5A |

| Cont.Current | 4.5A / Cooling 9A | 4.5A / Cooling 9A |

| Maximum torque (1 sec.) | 171Nm / Cooling 228Nm | 171Nm / Cooling 228Nm |

| Cont.torque | 57Nm / Cooling 114Nm | 57Nm / Cooling 114Nm |

| Minimum Increment | 0.001° | 0.001° |

| Signal format | Biss-C | Biss-C |

| Resolution | 26bit | 26bit |

| Positioning accuracy | ±20 (Arc.Sec.) | ±20 (Arc.Sec.) |

| Repeatability | within 10 Arc.Sec. | within 10 Arc.Sec. |

| Clamping Force | NO | 85 kgf-m |

| Net weight | 53 kg | kg |

- 1. The cooler is provided by customer.

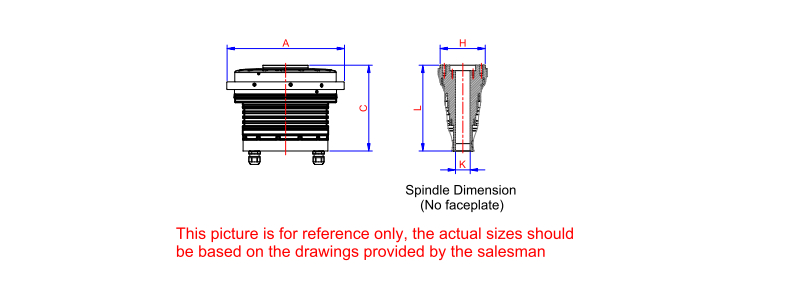

unit: mm

| DGB-301/ DGB-301P |

total width(A) | total height(C) | Spindle through hole(K) | Spindle outer diameter(H) | Spindle length(L) |

|---|---|---|---|---|---|

| No faceplate | 317 | 232 | Ø40 | Ø122 | 231.5 |