Photo

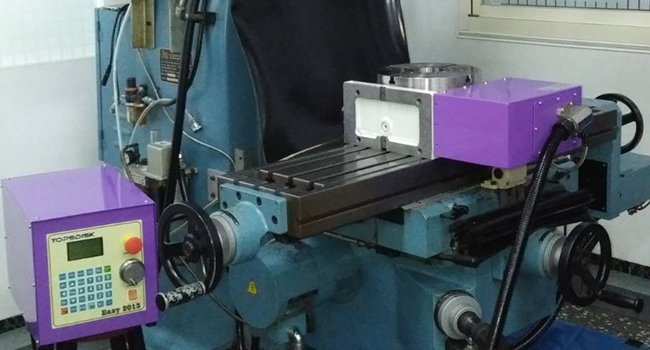

The controller can automatic indexing

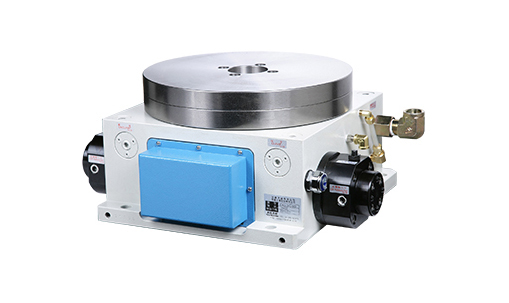

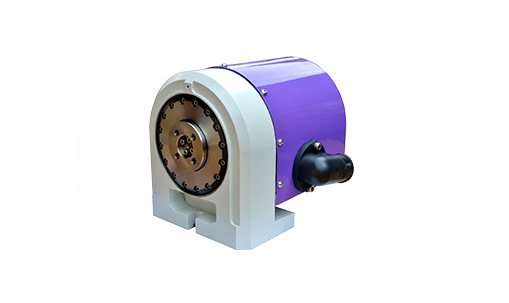

Indexing Rotary Table

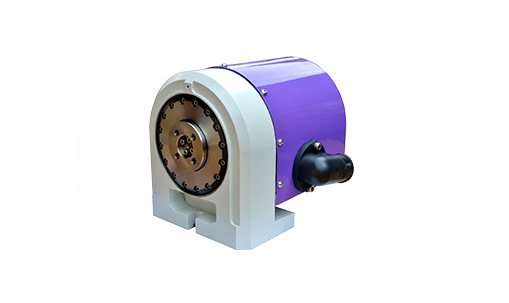

4th/5th Rotary Table

The controller can automatically index

Use Rotary Tables for Milling Machines Advantages

- Enhanced Versatility Rotary tables allow for multi-axis machining, enabling the milling machine to perform complex operations such as cutting arcs, circles, and curves, which would be challenging or impossible with a standard setup. This versatility expands the range of parts that can be produced.

- Increased Efficiency By enabling the machining of multiple sides or angles of a workpiece without repositioning it manually, rotary tables reduce setup time and increase overall machining efficiency. This feature is particularly beneficial for batch production or when machining intricate parts.

- Accurate Indexing Rotary tables provide precise indexing, allowing for accurate positioning of the workpiece at specific angles or divisions. This accuracy ensures consistency in part dimensions and helps achieve tight tolerances, crucial in industries such as aerospace and automotive.

- Cost-Effectiveness Despite their initial investment cost, rotary tables contribute to cost-effectiveness in the long run by streamlining production processes, reducing scrap, and minimizing the need for additional specialized equipment or manual interventions.

- Complex Geometry Machining With the ability to tilt, rotate, and position workpieces at various angles, rotary tables facilitate the machining of intricate geometries, including undercuts, compound angles, and irregular shapes, which are common in industries like mold making and prototyping.