Quality Policy

As the proverb goes, ' A workman must sharpen his tools if he wants to do his work well.

We great importance the quality of shipments, want to give the user a higher quality product. So invest heavily to constructed Precision Measurement Laboratory and the measurement of environmental control under the National Laboratory standards of thermostat 20° and humidity 45%.

- Main inspection equipment:

-

01Using the most advanced high-precision German Wenzel of Coordinate Measuring Machine - LH 87.

Maximum error value of measurement:1.8 μm + ( L/350mm ) μm

-

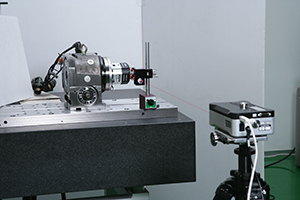

02British Renishaw XL-80 laser measurement system.

System accuracy: 0.5 ppm (Parts per million)

- 03German Mahr Digimar 817 CLM Height Measuring Instrument.

Maximum error value of precision: 1.8 μm + (L / 600mm) μm - 04Swiss TESA Micro-Hite 600 height measuring instrument.

Maximum error value of precision: 2+3L μm; Verticality: 9 μm - 05Japanese Mitutoyo LH-600 height measuring instrument.

Maximum error value of precision: 1.1 μm + ( 0.6L/600mm ) μm; Verticality: 5 μm

-

- Three quality management's insistence and commitment:

- Insistence of procurement of raw materials, parts, and commercially available products:

- Request outsourcing vendors must pay attention on the size and relative position, and are required to do inspection with Coordinate Measuring Machine, and enclose inspection report with purchase.

- When each purchase, the parts need to do a comprehensive secondary inspection with a complete inspection SOP and records to ensure achieve the best accuracy after that these parts are assembled.

- Insisted of the assembly process:

- Each production line are required to have a senior cadre to lead team members and co-assembly NC rotary table.

- After assembled, senior cadre must be responsible for quality control and inspection and fill in the inspection sheet.

- Insisted of packing before shipment:

- Inspecting and testing machine again, according the functions and the demands of the components before packing.

- After the final inspection is complete, must fill in a full inspection machine record sheet for future queries.